Let’s explore the process of making a bill of materials.

First set up the product’s components in the Odoo 17 Manufacturing module and then create a manufacturing order.

The BOM feature of Odoo 17 Manufacturing module lets you create a list of the components or raw materials required to build the product.

You will get the components listed automatically in the component tab, once the manufacturing order is developed using the relevant BOM. Examine this feature in the Manufacturing module.

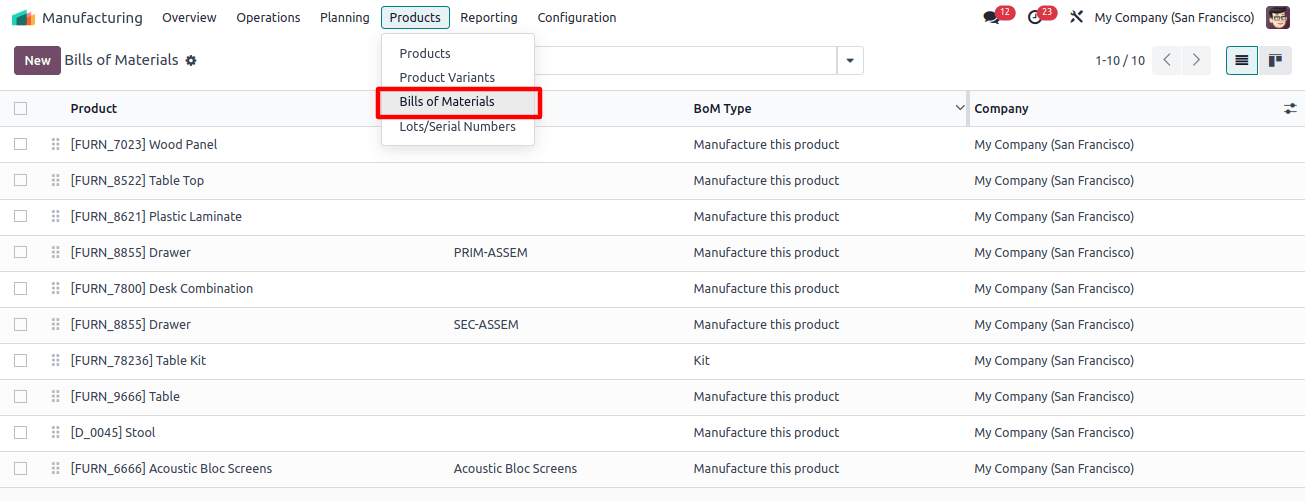

To generate a Bill of Material for a product, select the appropriate option from the Manufacturing module's Products menu. The window will display a list of BoM that have already been configured, as shown in the image below.

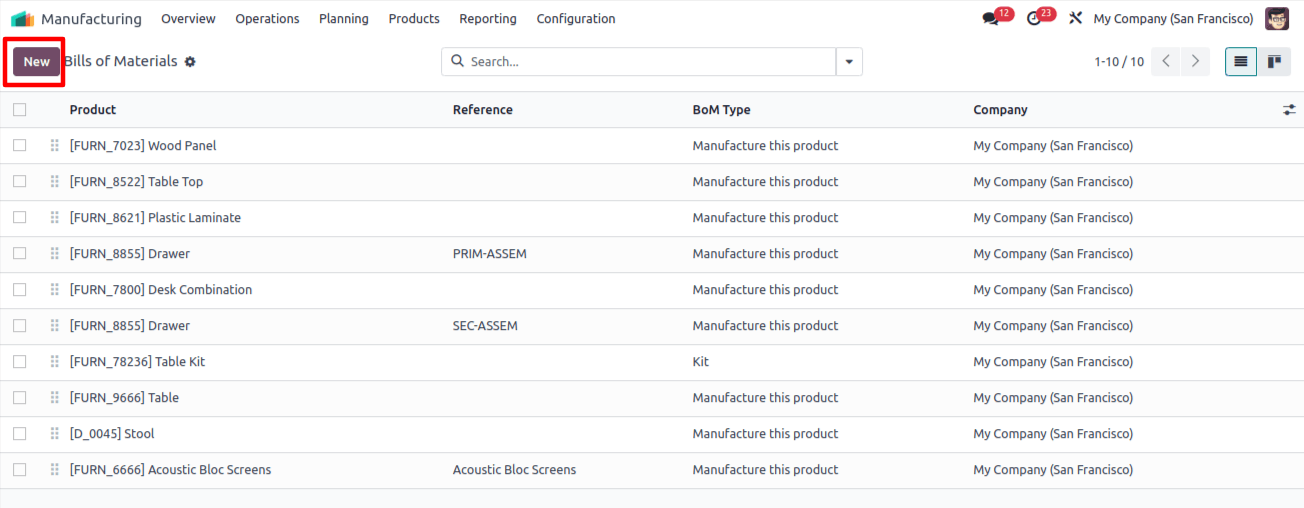

The list view includes details on the Product, Reference, BoM Type, and Company. To begin a new Bill of Materials, click the New button.

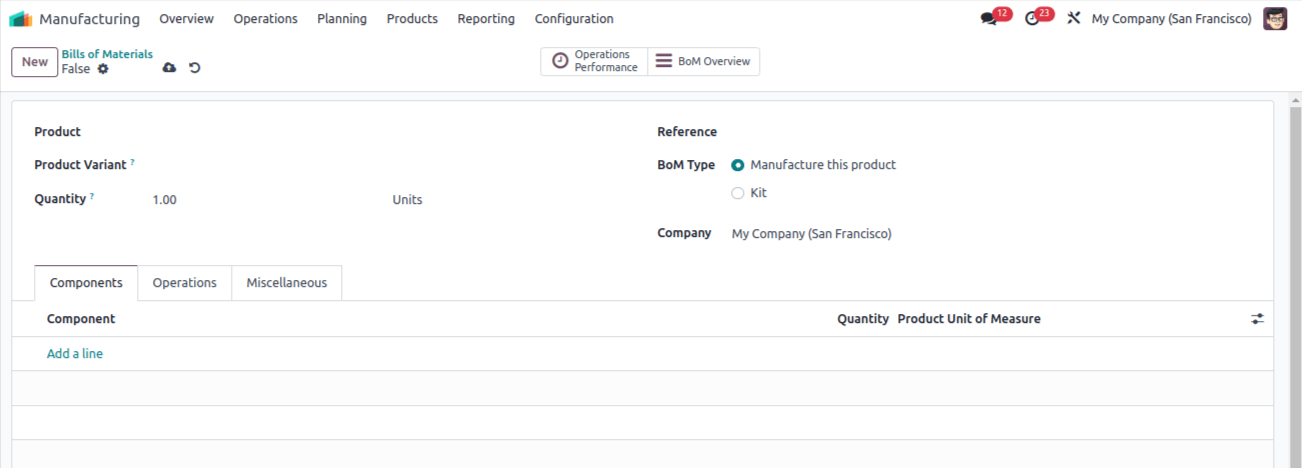

Now enter the Product, Product Variant, Reference, and Quantity that you intend to make in the appropriate fields.

You can create three different types of material bills in Odoo17. You can choose to subcontract, buy a kit, or manufacture this product yourself in the BoM Type area.

You can use the produce this Product option if you are creating this BoM in order to produce this product. Odoo lets you create Bills of Materials (BoMs) as kits! This means you can sell a bundle of products together as a single unit.

If you choose the Subcontracting option, this BOM will be used by the designated subcontractor to produce the product on your behalf. We will examine each of these BoM Types in turn.

Let's start by talking about how to draft a bill of materials for a manufacturing process.

Click the Add a Line button under the Components tab to enumerate each raw ingredient needed to make the given product. Don't forget to provide the necessary quantity of the component(s) in the Quantity area.

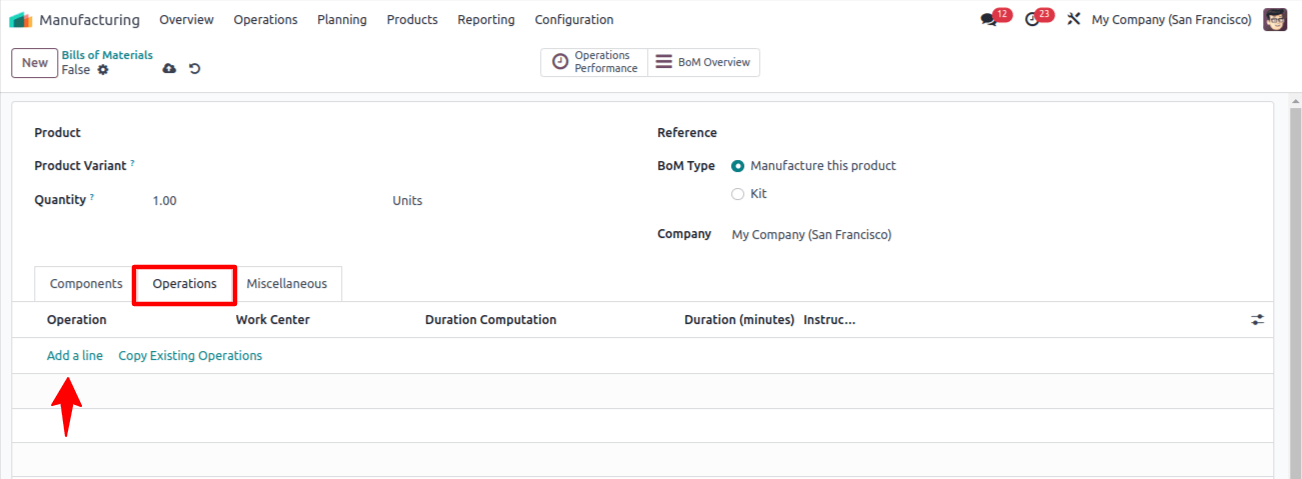

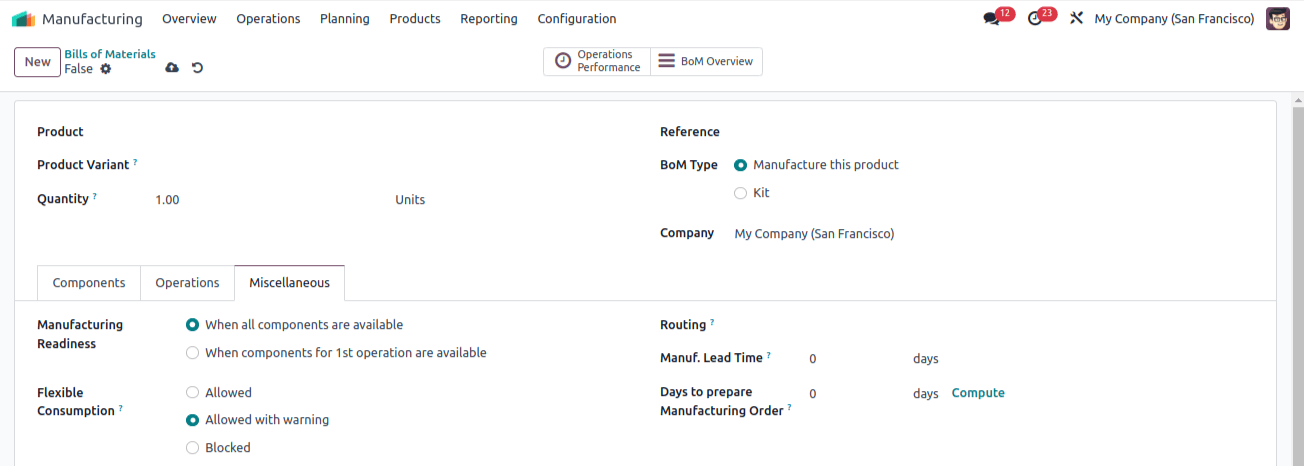

Under the activities tab, you can now add the activities allocated to the work centers to finish the product's manufacture. Using the corresponding button in the tab, you can duplicate the activities currently associated with the product. Alternatively, you can select Add a Line.

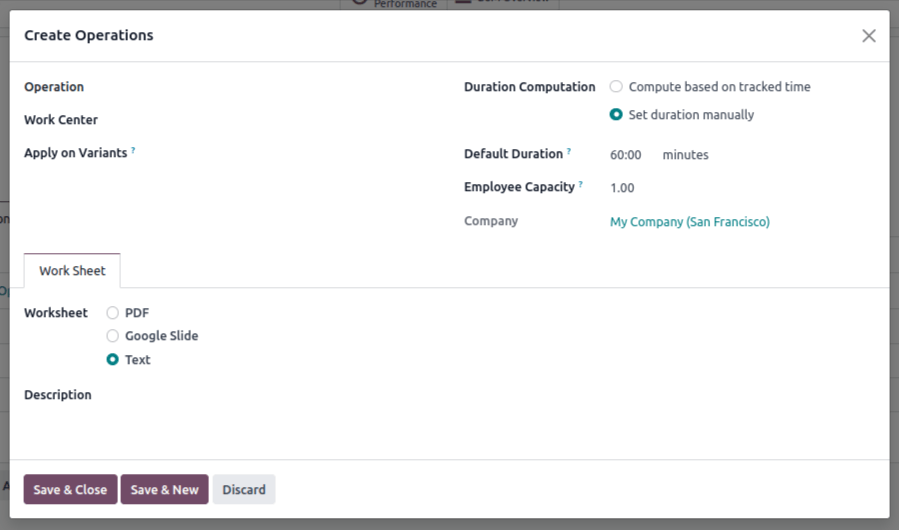

A pop-up window detailing the specifics of the operation will appear. Name the work center and the task that has to be completed in the appropriate fields. You can add product variations in the Apply on Variations section if the operation also applies to them.

You can modify the Duration Computation to meet your needs. Your two options are to calculate the operation's duration using recorded time or to set it manually. This is where the default duration will appear.

You can use the Employee Capacity parameter to specify how many employees are needed to finish this task.

You can add the procedure worksheet as a PDF, Google Slide, or text document. In addition to this, fill in the space provided with a description of the procedures used in the operation.

You can modify the Duration Computation to meet your needs. Your two options are to calculate the operation's duration using recorded time or to set it manually.

This is where the default duration will appear. You can use the Employee Capacity parameter to specify how many employees are needed to finish this task.

You can add the procedure worksheet as a PDF, Google Slide, or text document. In addition to this, fill in the space provided with a description of the procedures used in the operation.

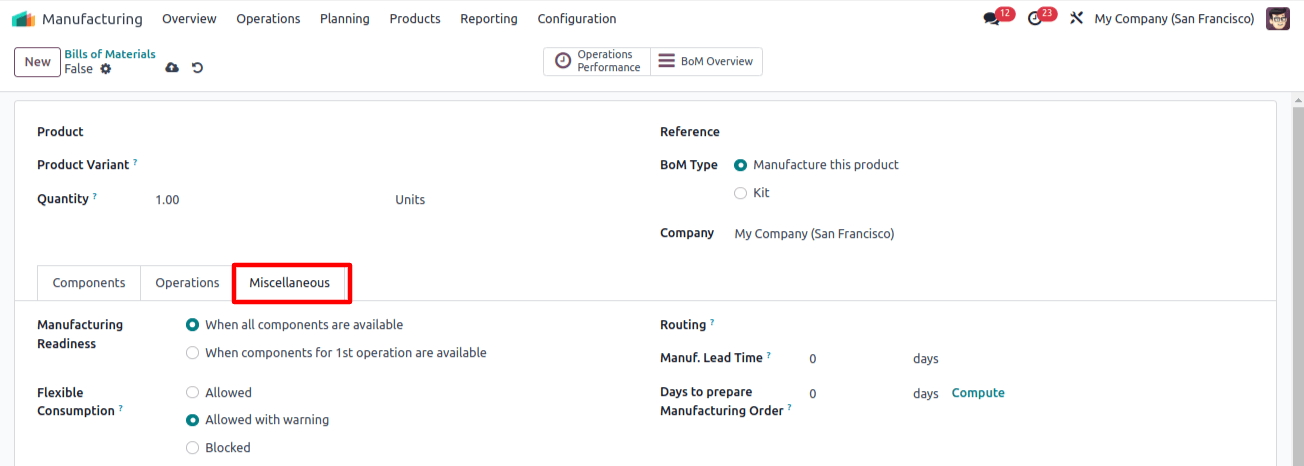

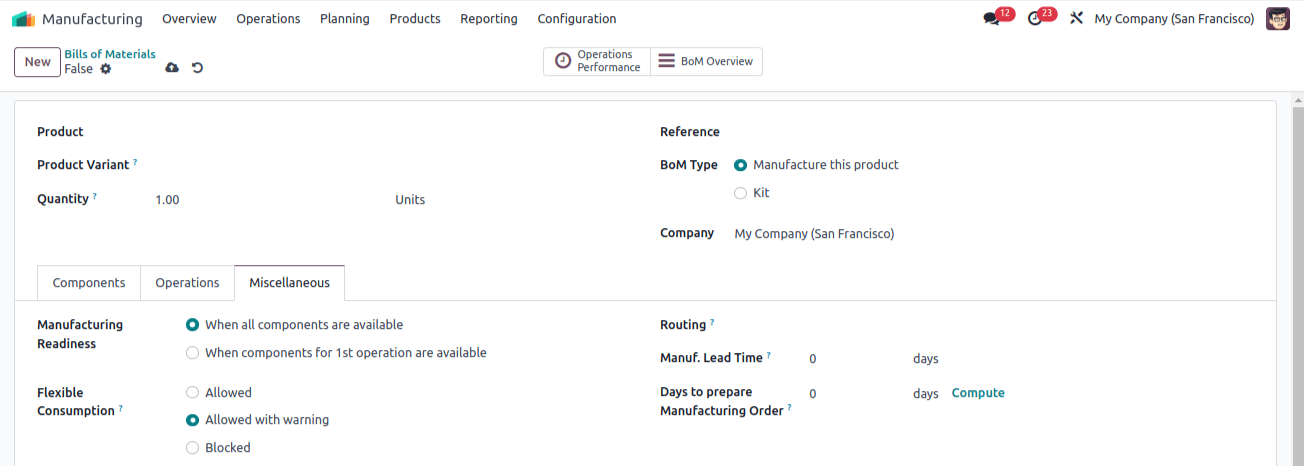

Manufacturing Lead Time: This is the typical amount of time needed to produce a product. The lead times for component manufacturing will rise in the case of a multi-BOM.

This can be used to figure out when parts need to be transported to the subcontractor if the product is being subcontracted.

Days needed to prepare manufacturing orders: To ensure you have enough time to produce semi-finished goods or replenish components, make sure you create and validate production orders well in advance.

Under the By-products tab, you can add the main product's associated by-products.

When purchasing observes that a "Manufacture" route has been specified, it will attempt to build a manufacturing order for a product using a Bill of Materials with the same operation type. Last but not least, you can create an analytical account to keep an eye on the BoM's earnings and expenses.

The finished BoM configuration can help you while you're putting together a production order for the related product.

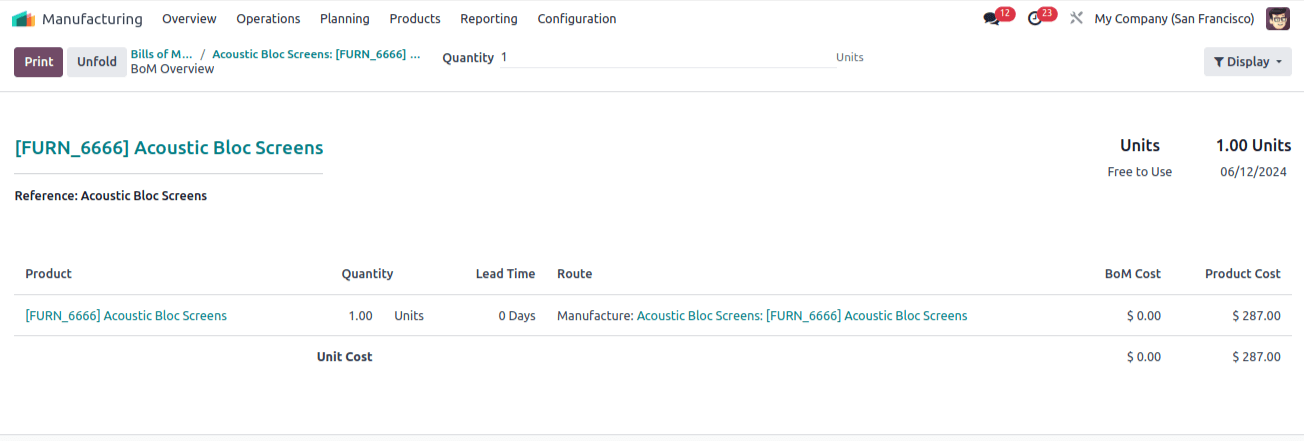

Through Operations Performance Smart, the duration of the work order associated with this routing will be measured and reported. For a comprehensive overview of the BoM, utilize the Overview smart button, as demonstrated below.

Details on the Product, Operations, Quantity, Free to Use/On Hand, Availability, Lead Time, Route, Bill of Materials Cost, and Product Cost are all included.

Kit

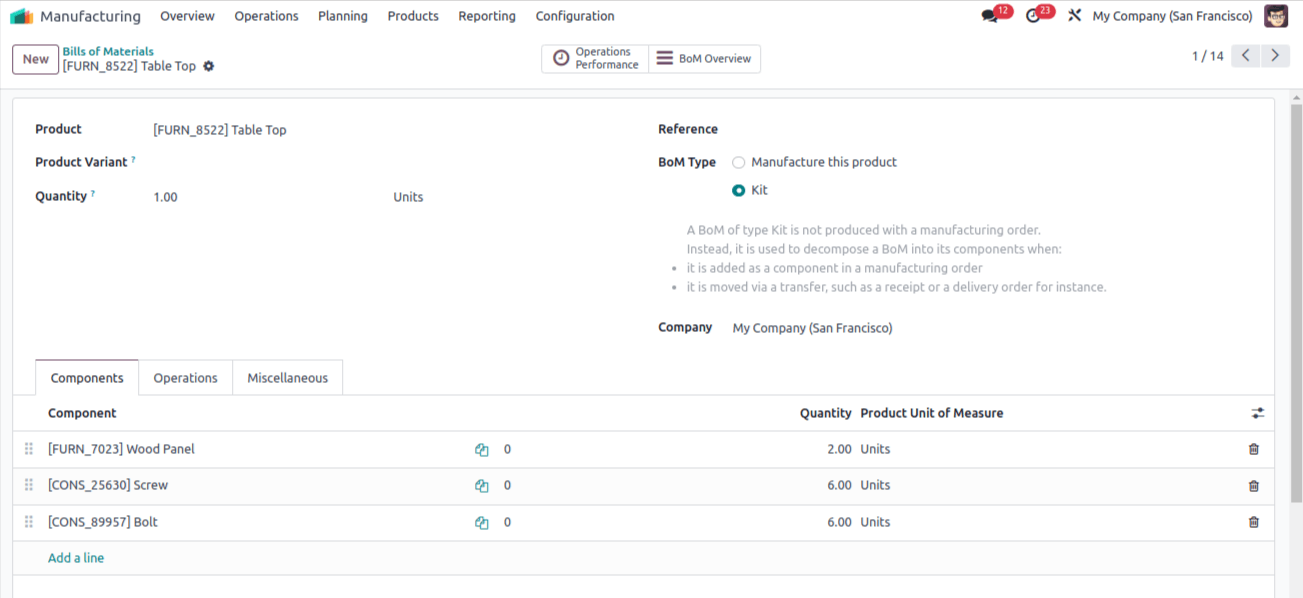

A product that can be sold as a complete unit is one that is assembled as a kit from many components. You will be prompted to choose the type of bill of materials when constructing one. This is where the Kit option appears. It allows you to assemble the parts into a kit and market it separately from the other products. Any changes made to the kit's inventory will affect every component.

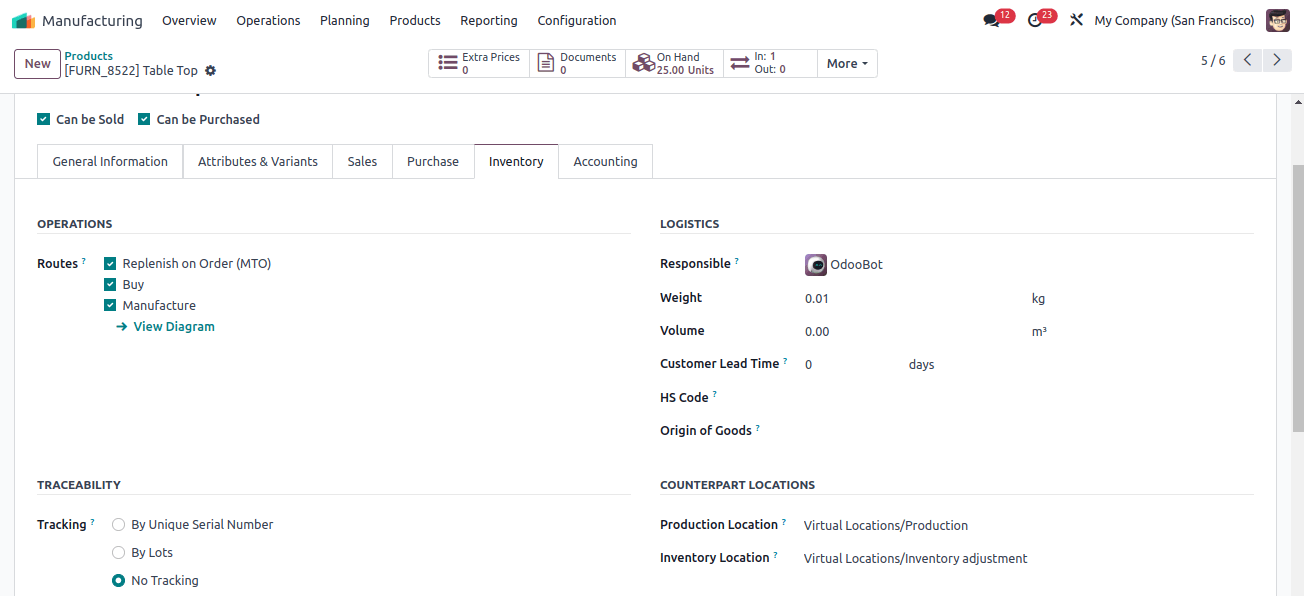

As seen in the illustration below, you can define a product in the products menu by naming the kit and selecting Manufacture as the Route of Operation.

To generate a bill for the primary product, go to the Bills of Materials configuration platform. Go to the Components tab and make a list of every product component after choosing the Kit BoM Type.

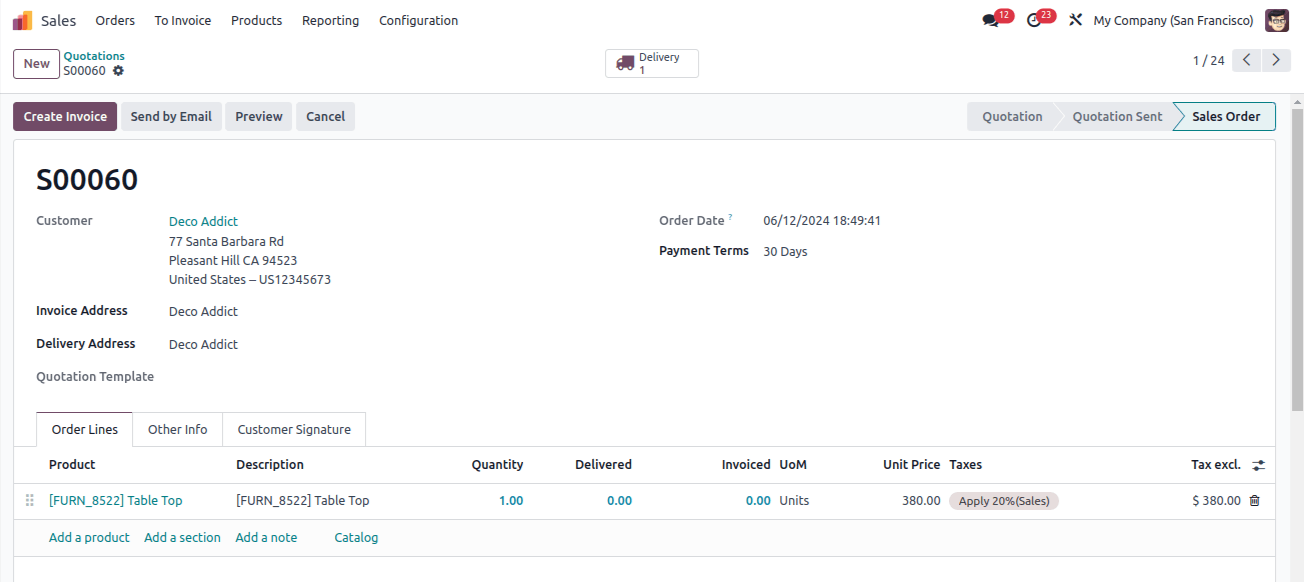

Once the Kit is configured, you can create a sales order to sell this item. From the Sales Orders order line select the main product.

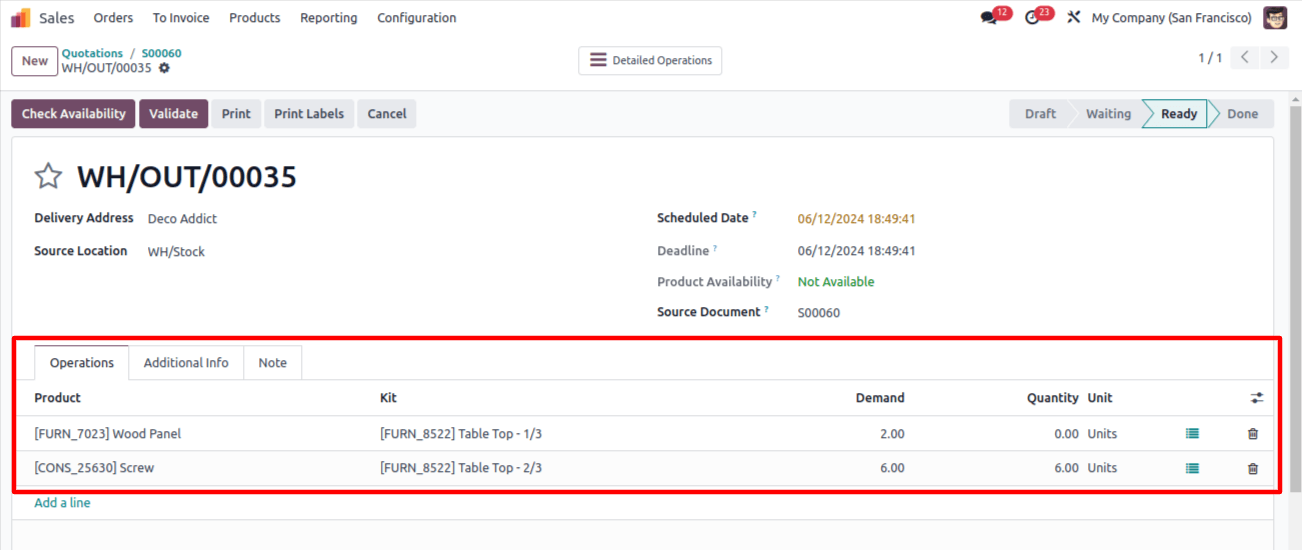

Once the sales order has been validated, review the delivery order to view the list of individual kit components on the operations page.

Using the inventory module, any parts that are missing when the sales order is validated can be added.

Subcontracting

It is not necessary for the business to manufacture every part of the products itself. You can appoint a subcontractor to create the parts while you concentrate more on assembling the parts you've previously purchased by using subcontracting.

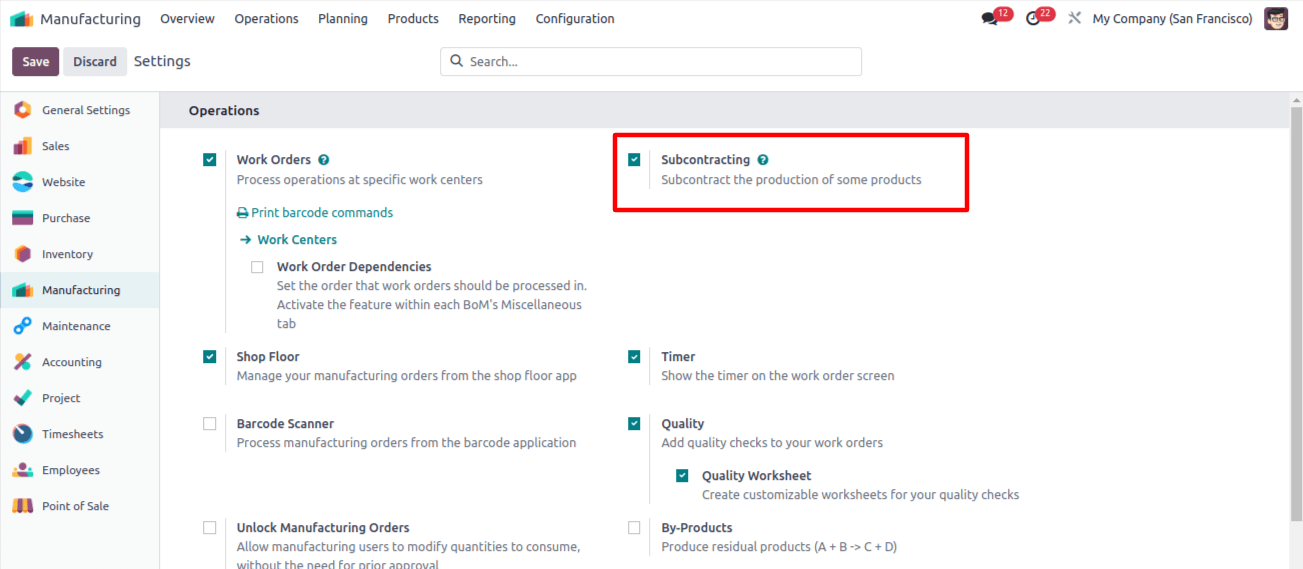

The subcontractor will maintain an on-site inventory of raw materials. From the settings menu turn on the subcontracting feature to add it to your Manufacturing module.

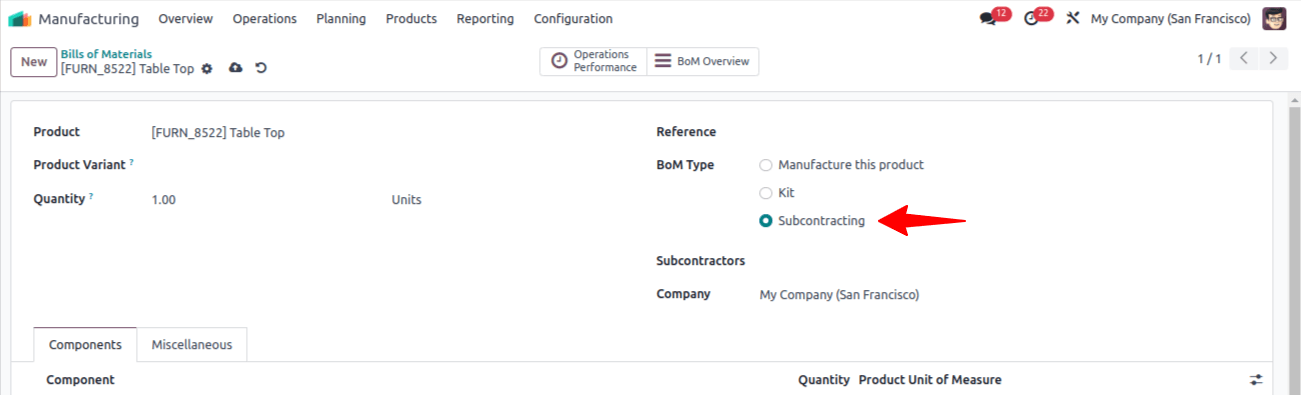

Once this functionality is enabled, you may make a new Bill of Material for the product by choosing Subcontracting as the BoM Type.

You will be able to enter the Subcontractor's name in a new field. To make your requirements easier for the subcontractor to understand, include the raw materials and their quantities under the Components tab.

You can create a buy order in the acquire module and get it from the appropriate subcontractor after establishing the subcontracting product.

In Conclusion, Odoo Services empower you to master Odoo 17 Manufacturing with comprehensive Bill of Materials support.

Related Post: