Work Center In Odoo 13 Manufacturing

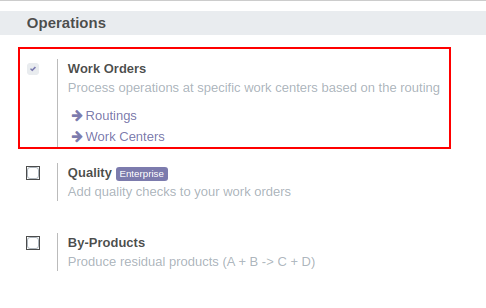

Once you have installed a manufacturing module and enable Work Orders to manage Work Centers.

Go to Configuration → Settings → Work Orders

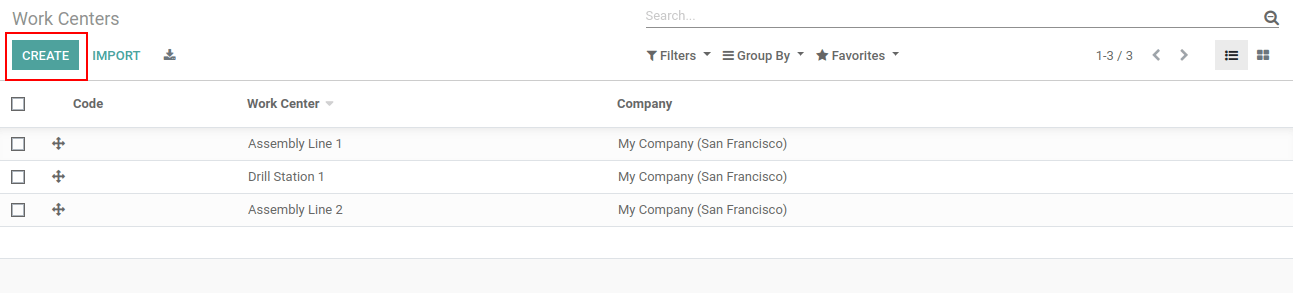

Once you enable Work Orders, You can see Work Center like this,

You can directly go to the Work Center from here or Create New Work Center.

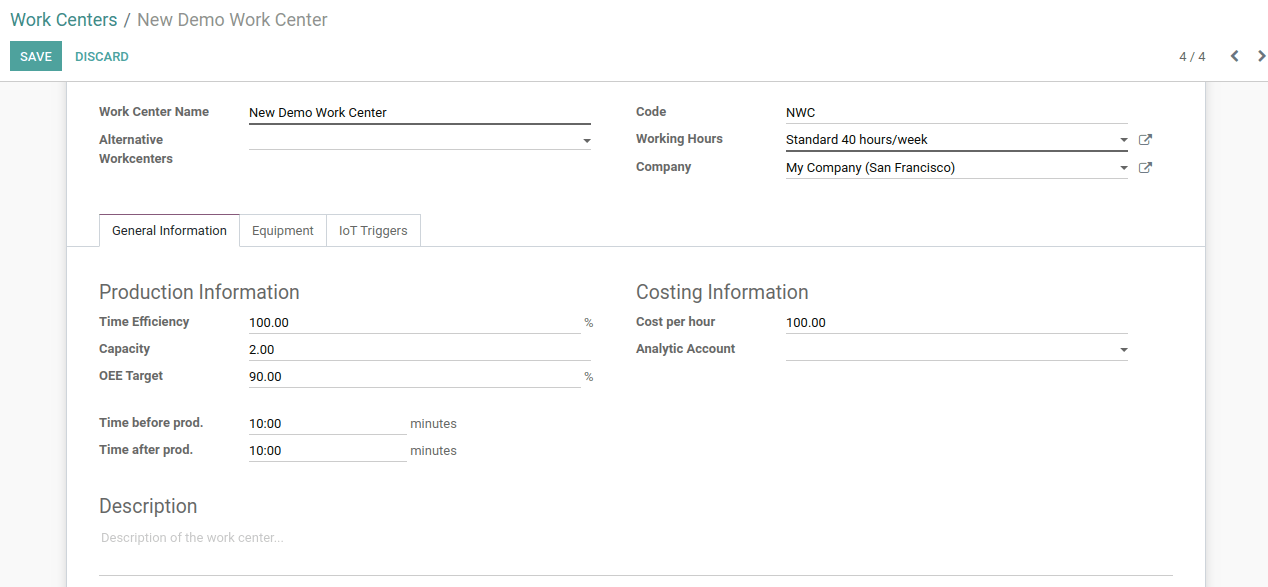

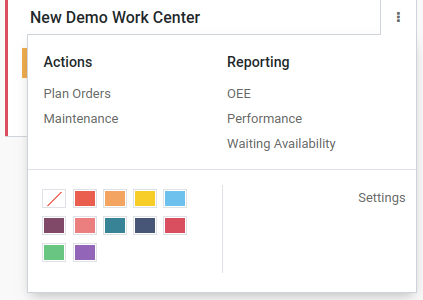

Create a New Work Center and Fill all the relevant details and There are some smart buttons available by which you can simplify the views based on that category.

Alternative work centers : This can be alternate or substitute to this Work Center in order to dispatch the production.

Time Efficiency : This field is for the expected duration of Work Order for this Work Center. For Example, If the Work Order can be completed in one hour and efficiency factor is 100% then this work can be done in one Hour and if efficiency factor is 50% then work is done in 2 Hours.

Capacity : Number of pieces or work can be produced parallel.

OEE Target : It means Overall Equipment Effectiveness (OEE) Target in percentage.

The time before prod : Time in minutes for some basic setup before start of a production.

Time after prod : Time in minutes for the cleaning once production has been completed

Description : This is for detailed description about the Work centers.

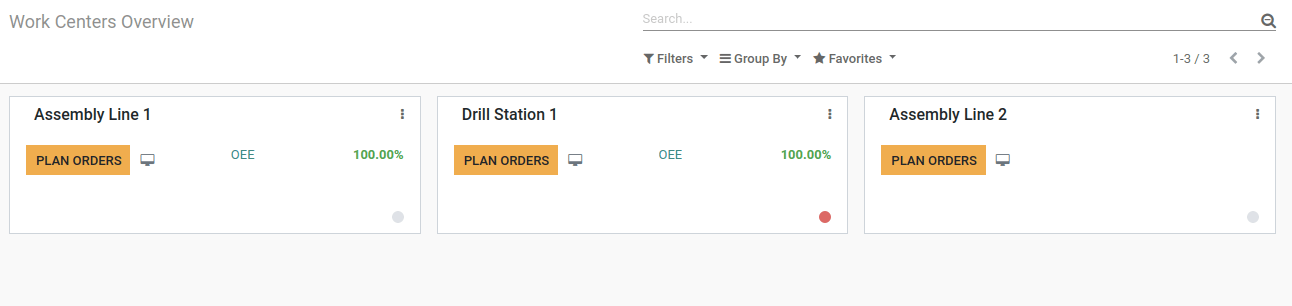

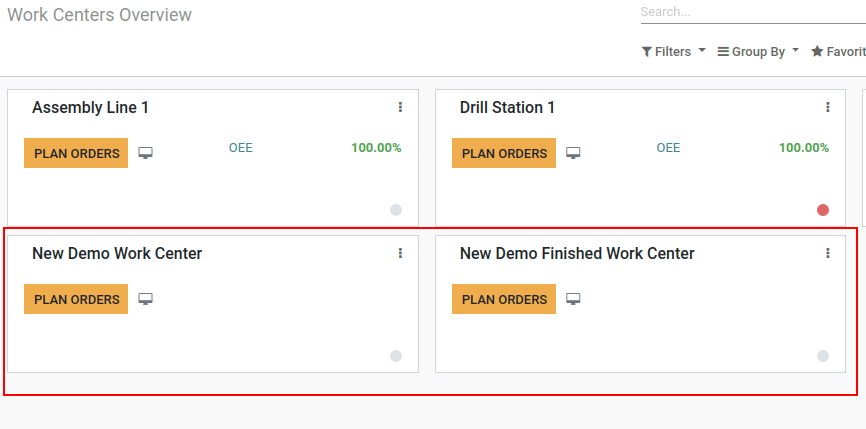

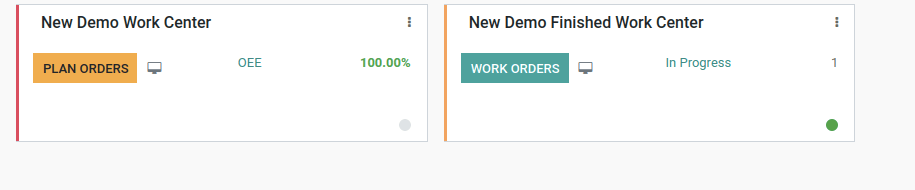

These are newly added Work Centers,

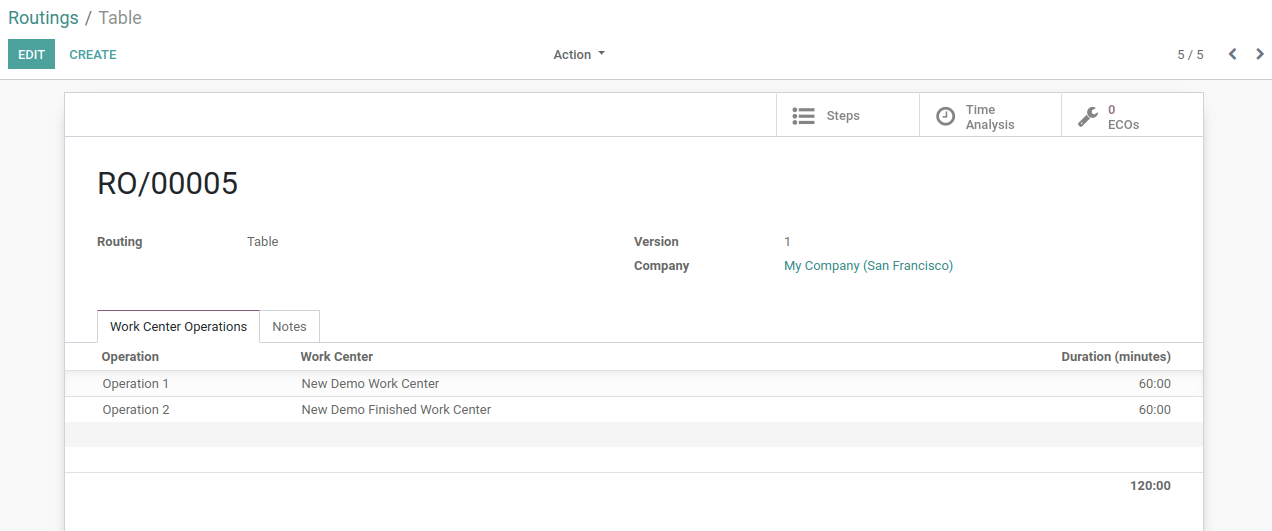

Routing

Once you create WorkCenter and the next step is to create new routing.

Go to Master Data → Routings

You can Add a line to define necessary Work Center operations.

- Give a Suitable name to Operation

- Easy to choose different work centers in routing a product

- Define Duration Computation based on Real Time or Set it manually and adjust default duration manually

- Start Next Operation : Once all products are processed OR Once some products are processed and Save it

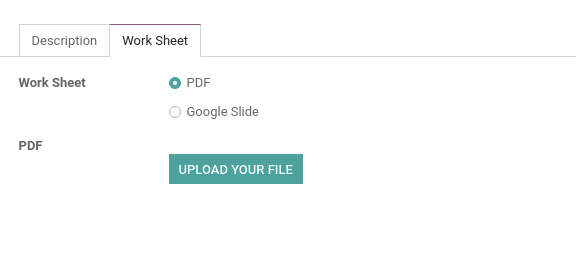

You can upload any file regarding the operations from Work-sheet Tab so it can be either PDF or Google Slide Document

Now, It requires to apply this routing to BOM

- Go to Master Data → Bills Of Materials

- Select a Product and Set the Routing to Table that we have created.

- You can change the BOM Type If it is required

- Save it

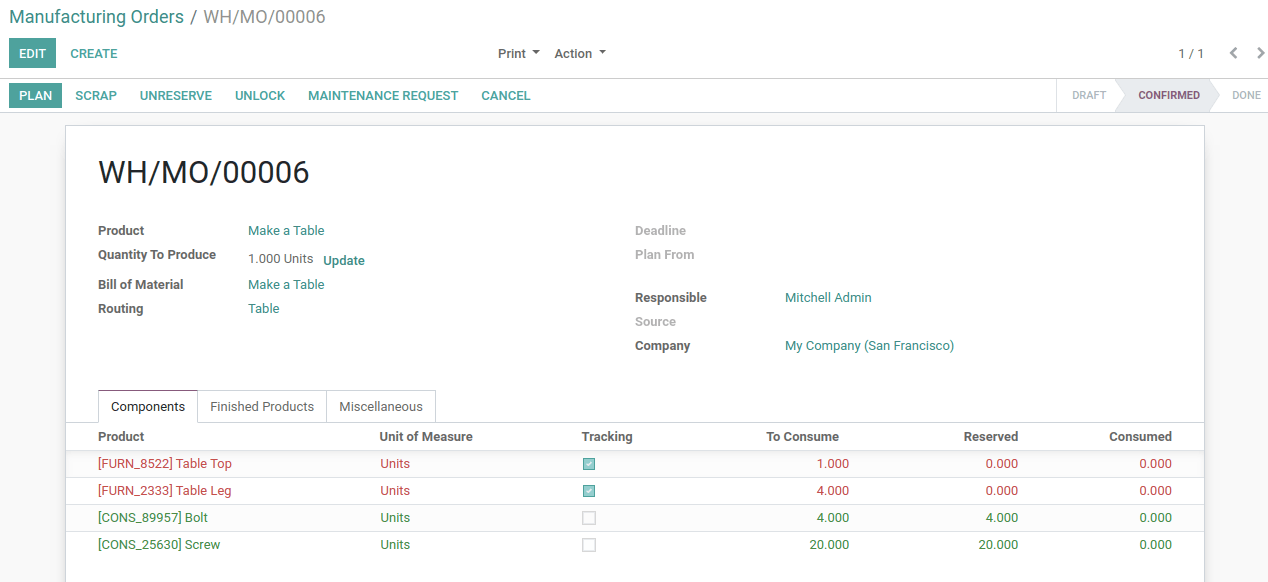

Manufacturing Order

Now We will create a Manufacturing Order to Make a Table

Go to Operations → Manufacturing Orders

Create a New Manufacturing Order

Select Product, Its Quantity, BoM and Save it

Check Availability of Material to see what is available

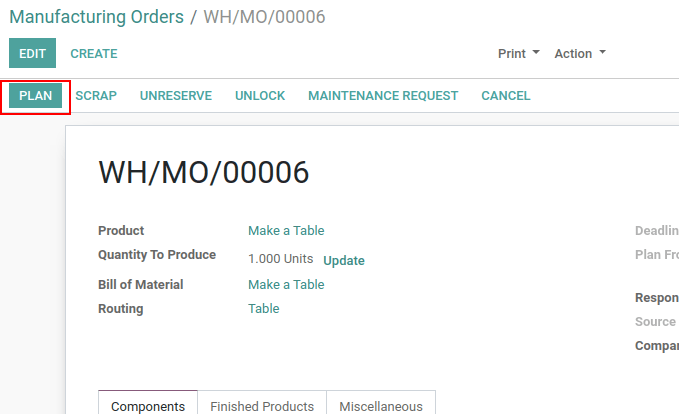

Now Click on the Plan button to start plan your order.

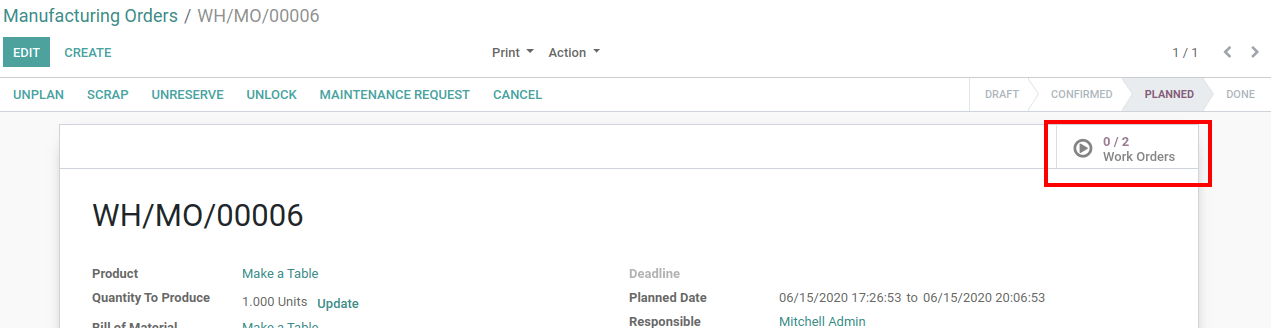

Once Click on Plan Button, It will show Work Orders on the top right corner of the Manufacturing order.

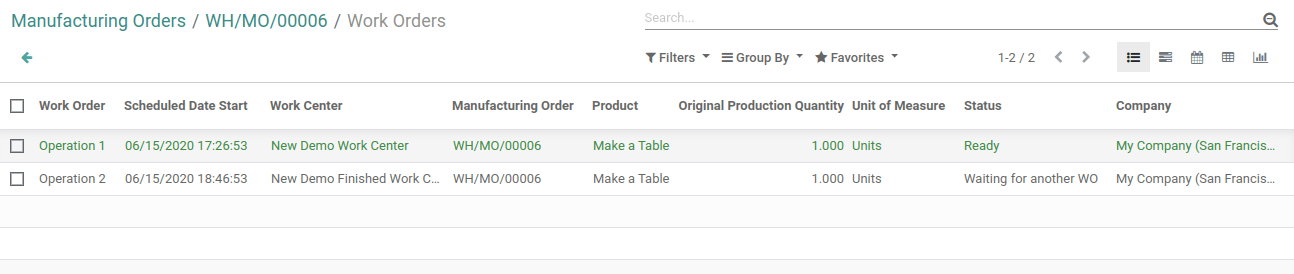

You can Click on the Work Orders to see the status of the orders.

- Here First Order is Ready and highlighted with Green Color so you can click on that order to complete it.

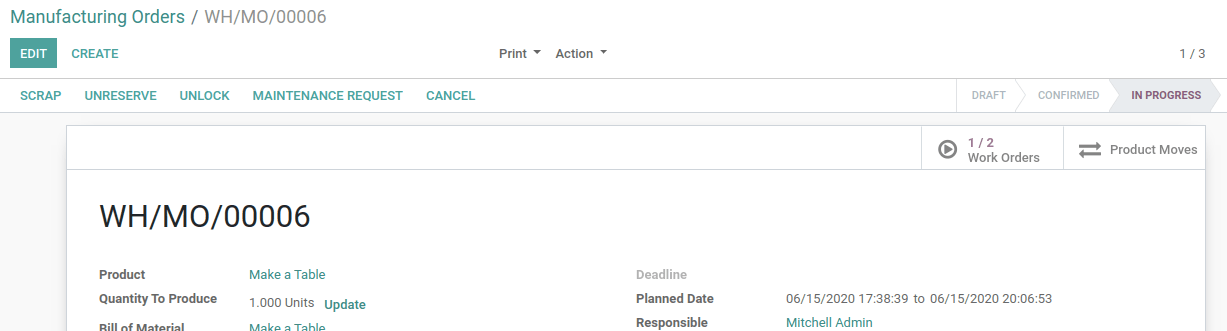

- Once you click on that order you can see the Process button to Start its Operation or You can Pause during production and continue with work later.

- Scrap which indicates the product that moves from Current Warehouse to any other

- Also easy to create Maintenance Request If it is required

- <li dir="ltr" sty