The Master Production Scheduler (MPS) in Odoo 17 is a tool for optimizing production planning and scheduling processes in industrial businesses. It enables businesses to meet client needs, manage resources more efficiently, and decrease expenses.

Users can create production plans based on demand estimates, sales, orders, and inventory levels, taking into account constraints such as production capacity, lead time, and material availability.

The MPS allows end-to-end supply chain visibility and real-time data interchange via module connections with inventory, sales, and purchasing.

Overall, the MPS helps businesses streamline procedures, increase efficiency, and respond quickly to customer needs.

This blog gives a detailed overview of the master production schedule feature in the Odoo 17 manufacturing module.

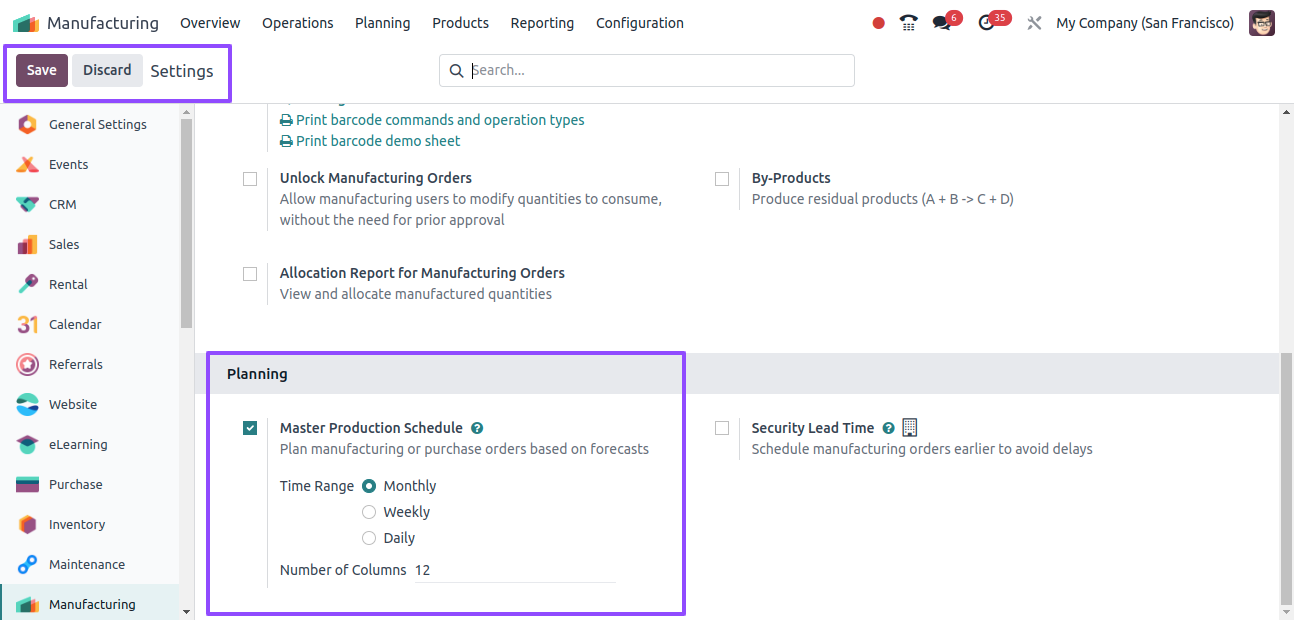

Setting up the Master Production Scheduler in Odoo

The "Master Production Schedule" option is located in the Odoo 17 Manufacturing Module's "Settings" window, under the "Planning" section. This is where you can enable the Master Production Scheduler feature, as shown in the image below.

The number of periods to be constantly presented, as well as the time interval for the Master Production Scheduler (MPS)—Monthly, Weekly, or Daily—may be specified inside the MPS options after the option has been enabled.

Planning Master Production Scheduler

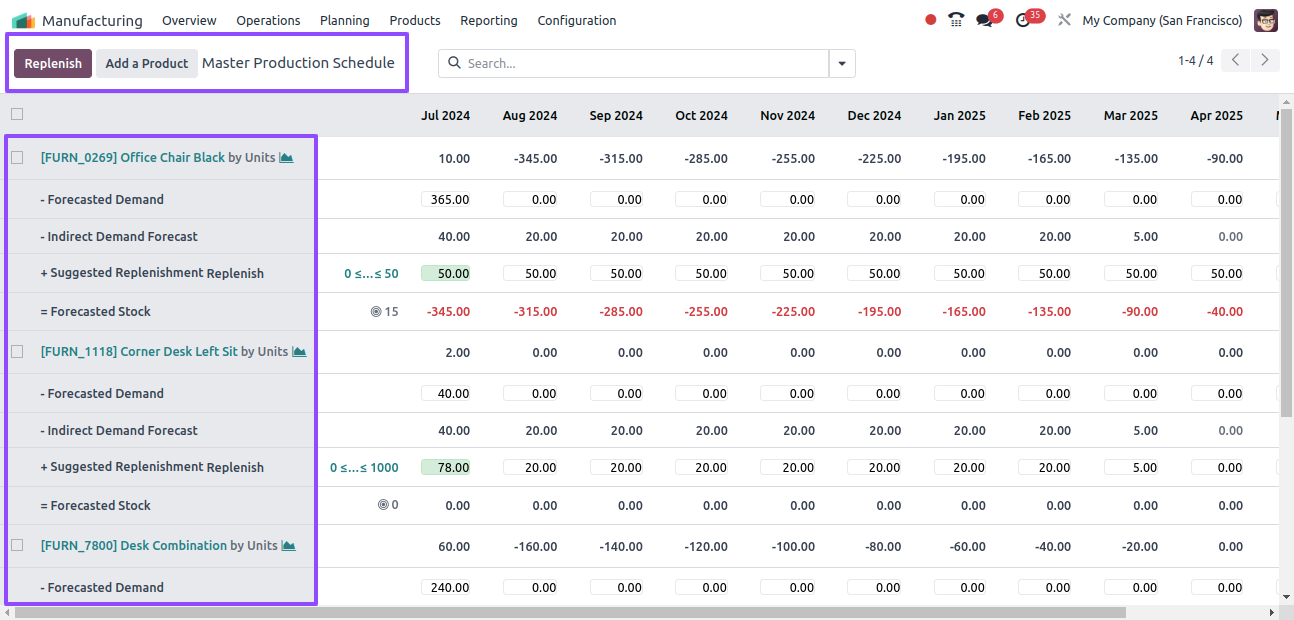

To start the planning process for a new master production schedule, go to the "Planning" menu and select the "Master Production Schedule" option.

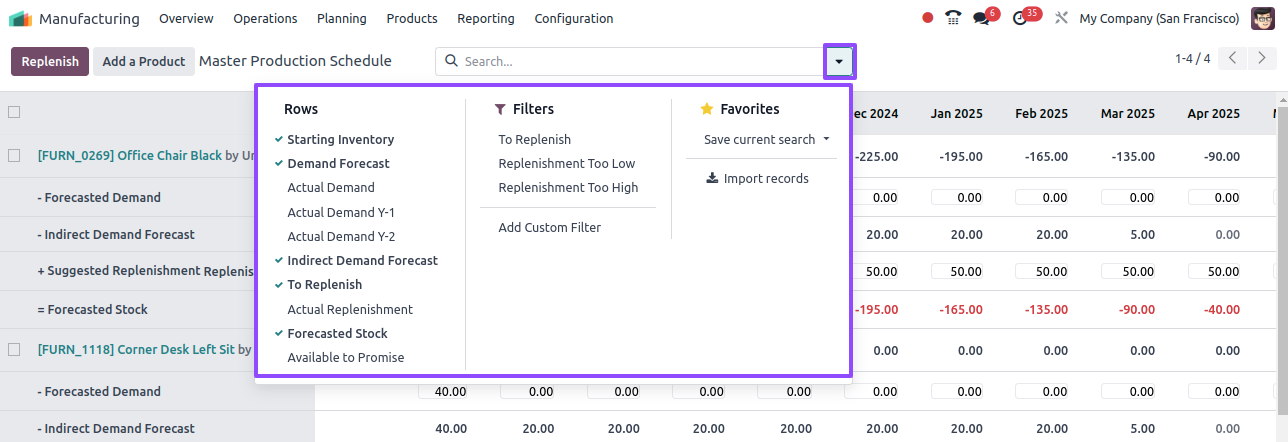

The screenshot below shows how users may choose which information is displayed in the MPS view by selecting the "Rows" option from the advanced search box.

This allows users to set variables such as starting inventory, actual demand, indirect demand forecast, replenishment, actual replenishment, forecasted stock, available to promise, and many others.

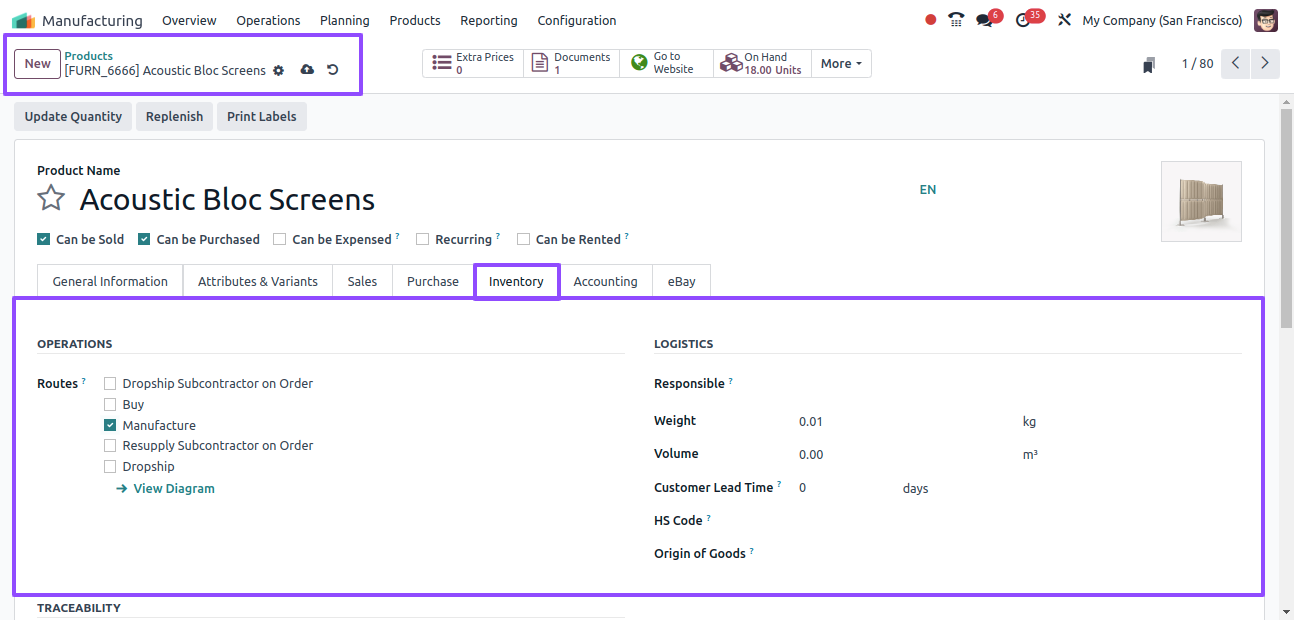

Setting Manufacturing Route

To enable Odoo to issue a manufacturing order upon replenishment, the needed product's "Routes" of operation must be set to "Manufacture" within the MPS.

As seen in the image below, this setting can be adjusted by selecting the "Inventory tab" of the specific product configuration form view from the "Products" menu.

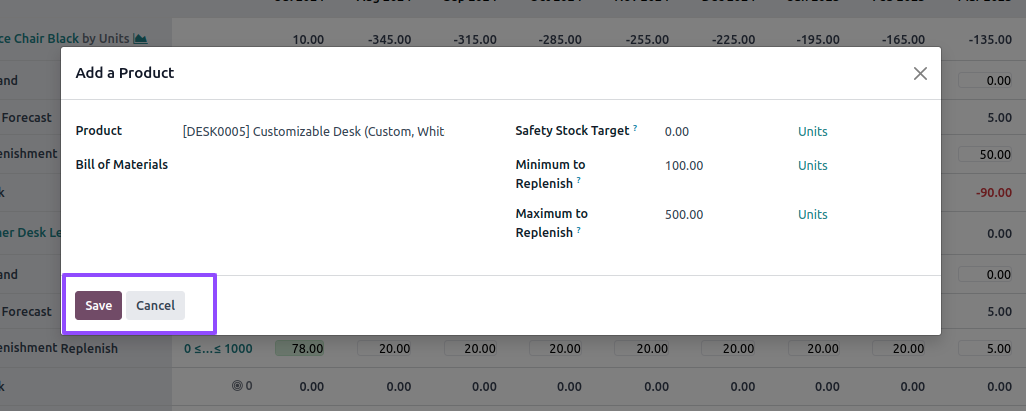

Adding a New Product in MPS

By presenting a form box where users may enter product details such as the product's name, bill of materials, and production warehouse, the "Add a Product" button makes it easier to add a new product to the Master Production Schedule.

Parameters like safety stock target, minimum to replenish, and maximum to replenish can be set to properly control inventory levels.

Once completed, users can save their changes by clicking the "Save" button, as shown in the image below.

The new product will be added to the MPS dashboard immediately, and information about supply levels for the following year, updated monthly, will be available.

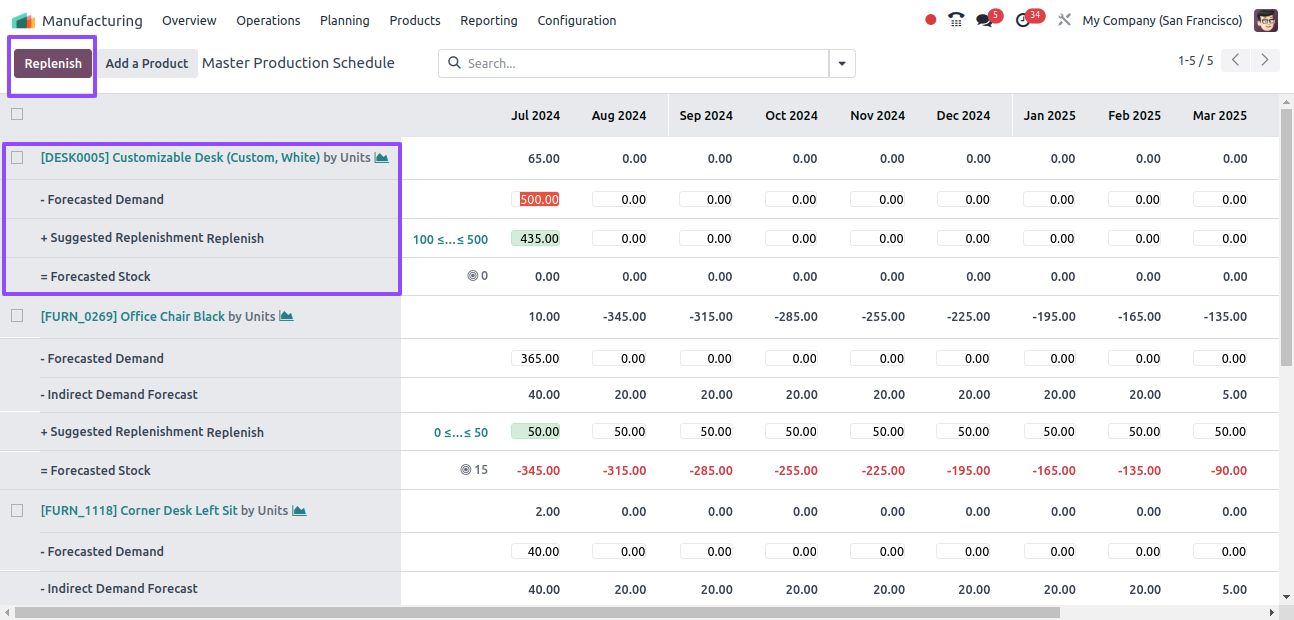

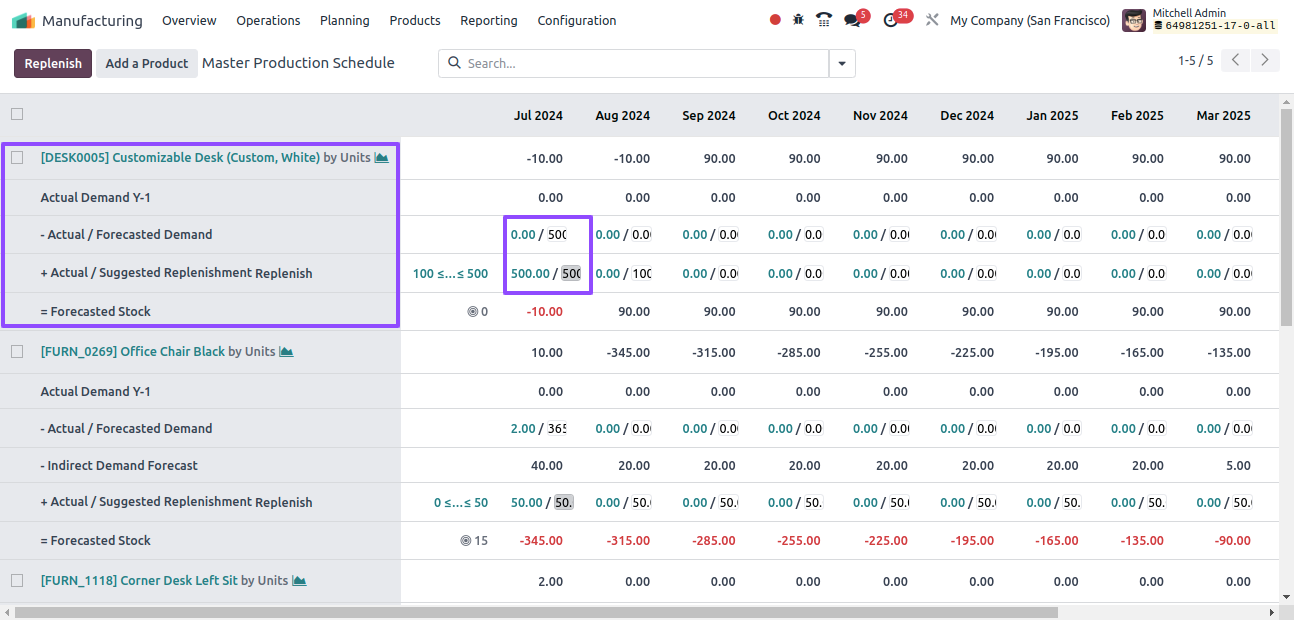

Users can manually enter predicted demand into the "Forecasted Demand" column, view proposed replenishment quantities in the "Suggested Replenishment" section, and see the projected stock available after each period in the "Forecasted Stock" field, as shown below.

Replenishing a Product

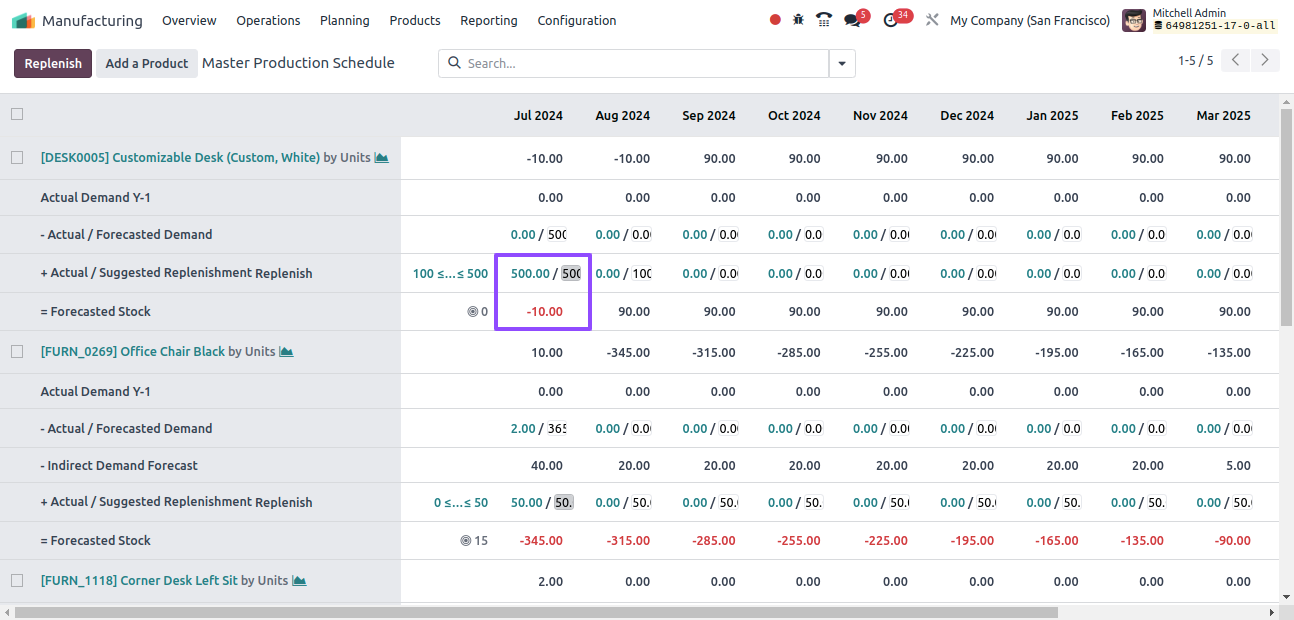

After setting up the 'Forecasted Demand,' the quantity to replenish for various periods is calculated automatically.

The replenishments based on lead times (vendor or manufacturer lead time) are highlighted in green and can be initiated by clicking the 'Replenish' button.

When you select the "Replenish" option, Odoo will produce a production or purchase order based on the product's operating route. These orders will be visible through the Manufacturing Orders portal, with MPS as the source.

If the suggested replenishment amount is manually adjusted, the cell’s left side will show a small cross. To return to the value that Odoo has automatically calculated, simply click the cross.

The cells within the suggested replenishment line have diverse colors to reflect different scenarios.

Green: Based on demand and indirect demand estimates, this indicates the number of products that need to be replenished to reach the predicted safety stock.

Gray: Shows that a replenishment order has been created and that the amount is in line with the most recent data.

Red: This indicates replenishment order was generated, but the quantity exceeded the current data.

Orange: Indicates that a replenishment order has been generated, but the quantity is insufficient according to current statistics.

Also, red cells may show within the forecasted stick line, indicating an expected negative stock level for the chosen period.

To summarize, the Master Production Scheduler in Odoo 17 is an effective tool for businesses looking to streamline production processes and improve productivity.

Its user-friendly interface and strong features allow users to manage schedules, maximize resource usage, and satisfy customer needs, resulting in increased control over manufacturing operations and performance in competitive markets.